A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property CI_URI::$config is deprecated

Filename: core/URI.php

Line Number: 101

Backtrace:

File: /home3/faqkosmy/public_html/labcoz.com/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property CI_Router::$uri is deprecated

Filename: core/Router.php

Line Number: 127

Backtrace:

File: /home3/faqkosmy/public_html/labcoz.com/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property Home::$benchmark is deprecated

Filename: core/Controller.php

Line Number: 82

Backtrace:

File: /home3/faqkosmy/public_html/labcoz.com/application/controllers/Home.php

File: /home3/faqkosmy/public_html/labcoz.com/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property Home::$hooks is deprecated

Filename: core/Controller.php

Line Number: 82

Backtrace:

File: /home3/faqkosmy/public_html/labcoz.com/application/controllers/Home.php

File: /home3/faqkosmy/public_html/labcoz.com/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property Home::$config is deprecated

Filename: core/Controller.php

Line Number: 82

Backtrace:

File: /home3/faqkosmy/public_html/labcoz.com/application/controllers/Home.php

File: /home3/faqkosmy/public_html/labcoz.com/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property Home::$log is deprecated

Filename: core/Controller.php

Line Number: 82

Backtrace:

File: /home3/faqkosmy/public_html/labcoz.com/application/controllers/Home.php

File: /home3/faqkosmy/public_html/labcoz.com/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property Home::$utf8 is deprecated

Filename: core/Controller.php

Line Number: 82

Backtrace:

File: /home3/faqkosmy/public_html/labcoz.com/application/controllers/Home.php

File: /home3/faqkosmy/public_html/labcoz.com/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property Home::$uri is deprecated

Filename: core/Controller.php

Line Number: 82

Backtrace:

File: /home3/faqkosmy/public_html/labcoz.com/application/controllers/Home.php

File: /home3/faqkosmy/public_html/labcoz.com/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property Home::$exceptions is deprecated

Filename: core/Controller.php

Line Number: 82

Backtrace:

File: /home3/faqkosmy/public_html/labcoz.com/application/controllers/Home.php

File: /home3/faqkosmy/public_html/labcoz.com/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property Home::$router is deprecated

Filename: core/Controller.php

Line Number: 82

Backtrace:

File: /home3/faqkosmy/public_html/labcoz.com/application/controllers/Home.php

File: /home3/faqkosmy/public_html/labcoz.com/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property Home::$output is deprecated

Filename: core/Controller.php

Line Number: 82

Backtrace:

File: /home3/faqkosmy/public_html/labcoz.com/application/controllers/Home.php

File: /home3/faqkosmy/public_html/labcoz.com/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property Home::$security is deprecated

Filename: core/Controller.php

Line Number: 82

Backtrace:

File: /home3/faqkosmy/public_html/labcoz.com/application/controllers/Home.php

File: /home3/faqkosmy/public_html/labcoz.com/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property Home::$input is deprecated

Filename: core/Controller.php

Line Number: 82

Backtrace:

File: /home3/faqkosmy/public_html/labcoz.com/application/controllers/Home.php

File: /home3/faqkosmy/public_html/labcoz.com/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property Home::$lang is deprecated

Filename: core/Controller.php

Line Number: 82

Backtrace:

File: /home3/faqkosmy/public_html/labcoz.com/application/controllers/Home.php

File: /home3/faqkosmy/public_html/labcoz.com/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property Home::$db is deprecated

Filename: core/Loader.php

Line Number: 396

Backtrace:

File: /home3/faqkosmy/public_html/labcoz.com/application/controllers/Home.php

File: /home3/faqkosmy/public_html/labcoz.com/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property CI_DB_mysqli_driver::$failover is deprecated

Filename: database/DB_driver.php

Line Number: 371

Backtrace:

File: /home3/faqkosmy/public_html/labcoz.com/application/controllers/Home.php

File: /home3/faqkosmy/public_html/labcoz.com/index.php

A PHP Error was encountered

Severity: 8192

Message: Return type of CI_Session_files_driver::open($save_path, $name) should either be compatible with SessionHandlerInterface::open(string $path, string $name): bool, or the #[\ReturnTypeWillChange] attribute should be used to temporarily suppress the notice

Filename: drivers/Session_files_driver.php

Line Number: 132

Backtrace:

File: /home3/faqkosmy/public_html/labcoz.com/application/controllers/Home.php

File: /home3/faqkosmy/public_html/labcoz.com/index.php

A PHP Error was encountered

Severity: 8192

Message: Return type of CI_Session_files_driver::close() should either be compatible with SessionHandlerInterface::close(): bool, or the #[\ReturnTypeWillChange] attribute should be used to temporarily suppress the notice

Filename: drivers/Session_files_driver.php

Line Number: 294

Backtrace:

File: /home3/faqkosmy/public_html/labcoz.com/application/controllers/Home.php

File: /home3/faqkosmy/public_html/labcoz.com/index.php

A PHP Error was encountered

Severity: 8192

Message: Return type of CI_Session_files_driver::read($session_id) should either be compatible with SessionHandlerInterface::read(string $id): string|false, or the #[\ReturnTypeWillChange] attribute should be used to temporarily suppress the notice

Filename: drivers/Session_files_driver.php

Line Number: 168

Backtrace:

File: /home3/faqkosmy/public_html/labcoz.com/application/controllers/Home.php

File: /home3/faqkosmy/public_html/labcoz.com/index.php

A PHP Error was encountered

Severity: 8192

Message: Return type of CI_Session_files_driver::write($session_id, $session_data) should either be compatible with SessionHandlerInterface::write(string $id, string $data): bool, or the #[\ReturnTypeWillChange] attribute should be used to temporarily suppress the notice

Filename: drivers/Session_files_driver.php

Line Number: 237

Backtrace:

File: /home3/faqkosmy/public_html/labcoz.com/application/controllers/Home.php

File: /home3/faqkosmy/public_html/labcoz.com/index.php

A PHP Error was encountered

Severity: 8192

Message: Return type of CI_Session_files_driver::destroy($session_id) should either be compatible with SessionHandlerInterface::destroy(string $id): bool, or the #[\ReturnTypeWillChange] attribute should be used to temporarily suppress the notice

Filename: drivers/Session_files_driver.php

Line Number: 317

Backtrace:

File: /home3/faqkosmy/public_html/labcoz.com/application/controllers/Home.php

File: /home3/faqkosmy/public_html/labcoz.com/index.php

A PHP Error was encountered

Severity: 8192

Message: Return type of CI_Session_files_driver::gc($maxlifetime) should either be compatible with SessionHandlerInterface::gc(int $max_lifetime): int|false, or the #[\ReturnTypeWillChange] attribute should be used to temporarily suppress the notice

Filename: drivers/Session_files_driver.php

Line Number: 358

Backtrace:

File: /home3/faqkosmy/public_html/labcoz.com/application/controllers/Home.php

File: /home3/faqkosmy/public_html/labcoz.com/index.php

A PHP Error was encountered

Severity: Warning

Message: ini_set(): Session ini settings cannot be changed after headers have already been sent

Filename: Session/Session.php

Line Number: 282

Backtrace:

File: /home3/faqkosmy/public_html/labcoz.com/application/controllers/Home.php

File: /home3/faqkosmy/public_html/labcoz.com/index.php

A PHP Error was encountered

Severity: Warning

Message: session_set_cookie_params(): Session cookie parameters cannot be changed after headers have already been sent

Filename: Session/Session.php

Line Number: 289

Backtrace:

File: /home3/faqkosmy/public_html/labcoz.com/application/controllers/Home.php

File: /home3/faqkosmy/public_html/labcoz.com/index.php

A PHP Error was encountered

Severity: Warning

Message: ini_set(): Session ini settings cannot be changed after headers have already been sent

Filename: Session/Session.php

Line Number: 304

Backtrace:

File: /home3/faqkosmy/public_html/labcoz.com/application/controllers/Home.php

File: /home3/faqkosmy/public_html/labcoz.com/index.php

A PHP Error was encountered

Severity: Warning

Message: ini_set(): Session ini settings cannot be changed after headers have already been sent

Filename: Session/Session.php

Line Number: 314

Backtrace:

File: /home3/faqkosmy/public_html/labcoz.com/application/controllers/Home.php

File: /home3/faqkosmy/public_html/labcoz.com/index.php

A PHP Error was encountered

Severity: Warning

Message: ini_set(): Session ini settings cannot be changed after headers have already been sent

Filename: Session/Session.php

Line Number: 315

Backtrace:

File: /home3/faqkosmy/public_html/labcoz.com/application/controllers/Home.php

File: /home3/faqkosmy/public_html/labcoz.com/index.php

A PHP Error was encountered

Severity: Warning

Message: ini_set(): Session ini settings cannot be changed after headers have already been sent

Filename: Session/Session.php

Line Number: 316

Backtrace:

File: /home3/faqkosmy/public_html/labcoz.com/application/controllers/Home.php

File: /home3/faqkosmy/public_html/labcoz.com/index.php

A PHP Error was encountered

Severity: Warning

Message: ini_set(): Session ini settings cannot be changed after headers have already been sent

Filename: Session/Session.php

Line Number: 317

Backtrace:

File: /home3/faqkosmy/public_html/labcoz.com/application/controllers/Home.php

File: /home3/faqkosmy/public_html/labcoz.com/index.php

A PHP Error was encountered

Severity: Warning

Message: ini_set(): Session ini settings cannot be changed after headers have already been sent

Filename: Session/Session.php

Line Number: 375

Backtrace:

File: /home3/faqkosmy/public_html/labcoz.com/application/controllers/Home.php

File: /home3/faqkosmy/public_html/labcoz.com/index.php

A PHP Error was encountered

Severity: Warning

Message: session_set_save_handler(): Session save handler cannot be changed after headers have already been sent

Filename: Session/Session.php

Line Number: 110

Backtrace:

File: /home3/faqkosmy/public_html/labcoz.com/application/controllers/Home.php

File: /home3/faqkosmy/public_html/labcoz.com/index.php

A PHP Error was encountered

Severity: Warning

Message: session_start(): Session cannot be started after headers have already been sent

Filename: Session/Session.php

Line Number: 143

Backtrace:

File: /home3/faqkosmy/public_html/labcoz.com/application/controllers/Home.php

File: /home3/faqkosmy/public_html/labcoz.com/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property Home::$session is deprecated

Filename: core/Loader.php

Line Number: 1283

Backtrace:

File: /home3/faqkosmy/public_html/labcoz.com/application/controllers/Home.php

File: /home3/faqkosmy/public_html/labcoz.com/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property Home::$email is deprecated

Filename: core/Loader.php

Line Number: 1283

Backtrace:

File: /home3/faqkosmy/public_html/labcoz.com/application/controllers/Home.php

File: /home3/faqkosmy/public_html/labcoz.com/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property Home::$cart is deprecated

Filename: core/Loader.php

Line Number: 1283

Backtrace:

File: /home3/faqkosmy/public_html/labcoz.com/application/controllers/Home.php

File: /home3/faqkosmy/public_html/labcoz.com/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property Home::$formval is deprecated

Filename: core/Loader.php

Line Number: 1283

Backtrace:

File: /home3/faqkosmy/public_html/labcoz.com/application/controllers/Home.php

File: /home3/faqkosmy/public_html/labcoz.com/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property Home::$agent is deprecated

Filename: core/Loader.php

Line Number: 1283

Backtrace:

File: /home3/faqkosmy/public_html/labcoz.com/application/controllers/Home.php

File: /home3/faqkosmy/public_html/labcoz.com/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property Home::$Main_model is deprecated

Filename: core/Loader.php

Line Number: 358

Backtrace:

File: /home3/faqkosmy/public_html/labcoz.com/application/controllers/Home.php

File: /home3/faqkosmy/public_html/labcoz.com/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property CI_Loader::$load is deprecated

Filename: core/Loader.php

Line Number: 931

Backtrace:

File: /home3/faqkosmy/public_html/labcoz.com/application/controllers/Home.php

File: /home3/faqkosmy/public_html/labcoz.com/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property CI_Loader::$benchmark is deprecated

Filename: core/Loader.php

Line Number: 931

Backtrace:

File: /home3/faqkosmy/public_html/labcoz.com/application/controllers/Home.php

File: /home3/faqkosmy/public_html/labcoz.com/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property CI_Loader::$hooks is deprecated

Filename: core/Loader.php

Line Number: 931

Backtrace:

File: /home3/faqkosmy/public_html/labcoz.com/application/controllers/Home.php

File: /home3/faqkosmy/public_html/labcoz.com/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property CI_Loader::$config is deprecated

Filename: core/Loader.php

Line Number: 931

Backtrace:

File: /home3/faqkosmy/public_html/labcoz.com/application/controllers/Home.php

File: /home3/faqkosmy/public_html/labcoz.com/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property CI_Loader::$log is deprecated

Filename: core/Loader.php

Line Number: 931

Backtrace:

File: /home3/faqkosmy/public_html/labcoz.com/application/controllers/Home.php

File: /home3/faqkosmy/public_html/labcoz.com/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property CI_Loader::$utf8 is deprecated

Filename: core/Loader.php

Line Number: 931

Backtrace:

File: /home3/faqkosmy/public_html/labcoz.com/application/controllers/Home.php

File: /home3/faqkosmy/public_html/labcoz.com/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property CI_Loader::$uri is deprecated

Filename: core/Loader.php

Line Number: 931

Backtrace:

File: /home3/faqkosmy/public_html/labcoz.com/application/controllers/Home.php

File: /home3/faqkosmy/public_html/labcoz.com/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property CI_Loader::$exceptions is deprecated

Filename: core/Loader.php

Line Number: 931

Backtrace:

File: /home3/faqkosmy/public_html/labcoz.com/application/controllers/Home.php

File: /home3/faqkosmy/public_html/labcoz.com/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property CI_Loader::$router is deprecated

Filename: core/Loader.php

Line Number: 931

Backtrace:

File: /home3/faqkosmy/public_html/labcoz.com/application/controllers/Home.php

File: /home3/faqkosmy/public_html/labcoz.com/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property CI_Loader::$output is deprecated

Filename: core/Loader.php

Line Number: 931

Backtrace:

File: /home3/faqkosmy/public_html/labcoz.com/application/controllers/Home.php

File: /home3/faqkosmy/public_html/labcoz.com/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property CI_Loader::$security is deprecated

Filename: core/Loader.php

Line Number: 931

Backtrace:

File: /home3/faqkosmy/public_html/labcoz.com/application/controllers/Home.php

File: /home3/faqkosmy/public_html/labcoz.com/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property CI_Loader::$input is deprecated

Filename: core/Loader.php

Line Number: 931

Backtrace:

File: /home3/faqkosmy/public_html/labcoz.com/application/controllers/Home.php

File: /home3/faqkosmy/public_html/labcoz.com/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property CI_Loader::$lang is deprecated

Filename: core/Loader.php

Line Number: 931

Backtrace:

File: /home3/faqkosmy/public_html/labcoz.com/application/controllers/Home.php

File: /home3/faqkosmy/public_html/labcoz.com/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property CI_Loader::$db is deprecated

Filename: core/Loader.php

Line Number: 931

Backtrace:

File: /home3/faqkosmy/public_html/labcoz.com/application/controllers/Home.php

File: /home3/faqkosmy/public_html/labcoz.com/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property CI_Loader::$session is deprecated

Filename: core/Loader.php

Line Number: 931

Backtrace:

File: /home3/faqkosmy/public_html/labcoz.com/application/controllers/Home.php

File: /home3/faqkosmy/public_html/labcoz.com/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property CI_Loader::$email is deprecated

Filename: core/Loader.php

Line Number: 931

Backtrace:

File: /home3/faqkosmy/public_html/labcoz.com/application/controllers/Home.php

File: /home3/faqkosmy/public_html/labcoz.com/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property CI_Loader::$cart is deprecated

Filename: core/Loader.php

Line Number: 931

Backtrace:

File: /home3/faqkosmy/public_html/labcoz.com/application/controllers/Home.php

File: /home3/faqkosmy/public_html/labcoz.com/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property CI_Loader::$formval is deprecated

Filename: core/Loader.php

Line Number: 931

Backtrace:

File: /home3/faqkosmy/public_html/labcoz.com/application/controllers/Home.php

File: /home3/faqkosmy/public_html/labcoz.com/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property CI_Loader::$agent is deprecated

Filename: core/Loader.php

Line Number: 931

Backtrace:

File: /home3/faqkosmy/public_html/labcoz.com/application/controllers/Home.php

File: /home3/faqkosmy/public_html/labcoz.com/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property CI_Loader::$Main_model is deprecated

Filename: core/Loader.php

Line Number: 931

Backtrace:

File: /home3/faqkosmy/public_html/labcoz.com/application/controllers/Home.php

File: /home3/faqkosmy/public_html/labcoz.com/index.php

labcoz

Get Quote

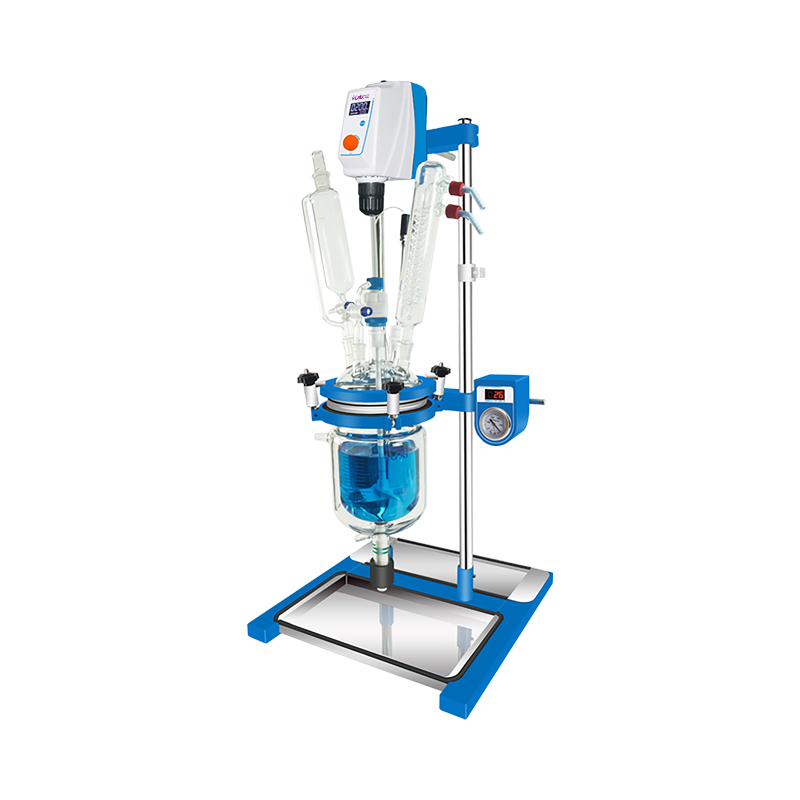

Overview

Glass Reactor LC-GR101 is a powerful device with a 1L tank capacity. It is a speed-regulation glass reactor that is mainly used for synthesis reactions. Circulating liquid of a certain temperature is injected into the reactor's interlayer so that the reactor's materials can be exposed to the required temperature from 80 to 200 ℃. As per the need, the kettle can be evacuated to a vacuum, to undergo a reaction utilizing negative pressure.

Specifications :

Volume of The Kettle

1 L

Kettle Jacket Volume

About 0.3 L

Condensation Area

About 0.025 m2

Pressure Funnel Volume

200 mL

Agitator Insertion Hole

24# standard grinding mouth

Temperature Sensor Insertion Hole

24# standard grinding mouth

Condenser Connection Port

24# standard grinding mouth

Liquid Feed Port

19# standard grinding mouth

Pressure Funnel Interface

24# standard grinding mouth

Working Temperature of Kettle

-80 to 200 ℃

Temperature Display Accuracy

±0.1 ℃

Limit Of Temperature Difference Inside and Outside the Kettle

≤80 ℃

Pressure In the Kettle

-0.1 to 0.0 MPa

Jacket Pressure

≤+0.03 MPa

Vacuum System Boost Rate

≤2 kPa/h

Speed Mode

Coarse and fine-tuning

Speed Range

50 to 500 rpm

Speed Display

LCD

Timing Range

1 to 9999 min

Stirring Time Setting

Yes

Speed Display Resolution

±1 rpm

Speed Memory

Yes

Torque

70 N.cm

Viscosity

≤10000 mPas

Stirring Paddle Fixing Method

Self-locking collet

Drill Chuck Clamping Diameter Range

0.5 to 10 mm

Temperature Sensor Type

PT100

Motor-Rated Power

70 W

Features :

- The parts that meet the liquid are made of highly corrosion-resistant and high-low temperature-resistant borosilicate glass or PTFE material

- By maintaining the low coefficient of linear expansion, it can withstand large thermal shock

- Removable discharge valve easily discharges the reactor material Standardized connection method, convenient and quick disassembly

- The temperature vacuum test is designed conveniently for accurately grasping the temperature and vacuum in the kettle

- The negative pressure can reach up to 0.095 MPa in the vacuum state

- Overhead agitator is equipped with an imported agitator-bearing sleeve

- Adopts overload and motor protection system withstanding the aggressive conditions

Applications :

Glass Reactor is used in a variety of process operations like the dissolution of solids, product mixing, chemical reactions, batch distillation, crystallization, extraction, and polymerization processes in laboratories and other research fields.

203 Fake St. Mountain View, San Francisco, California, USA

Email: info@labcoz.com | Website:

www.labcoz.com

Copyright labcoz . All

Rights Reserved.